03

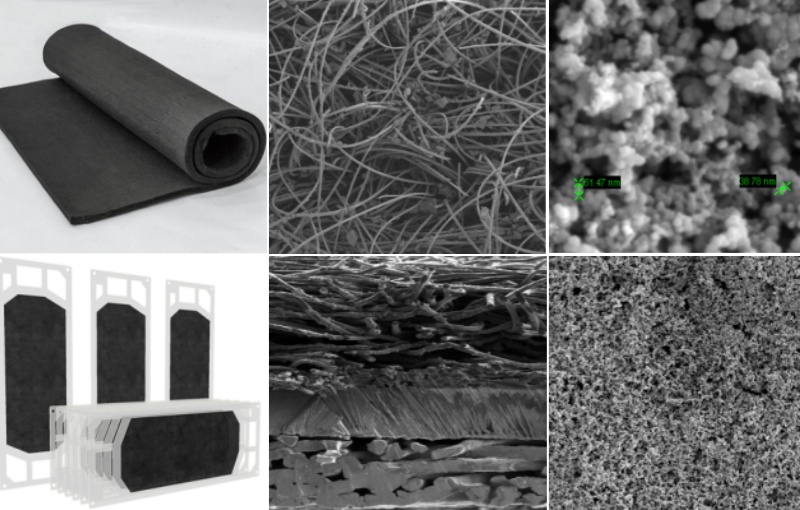

Master the preparation techniques and processes of various forms of electrodes

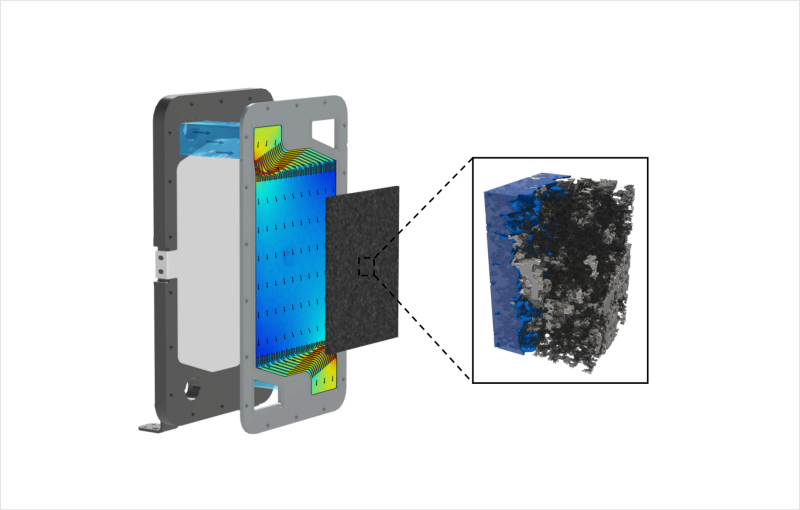

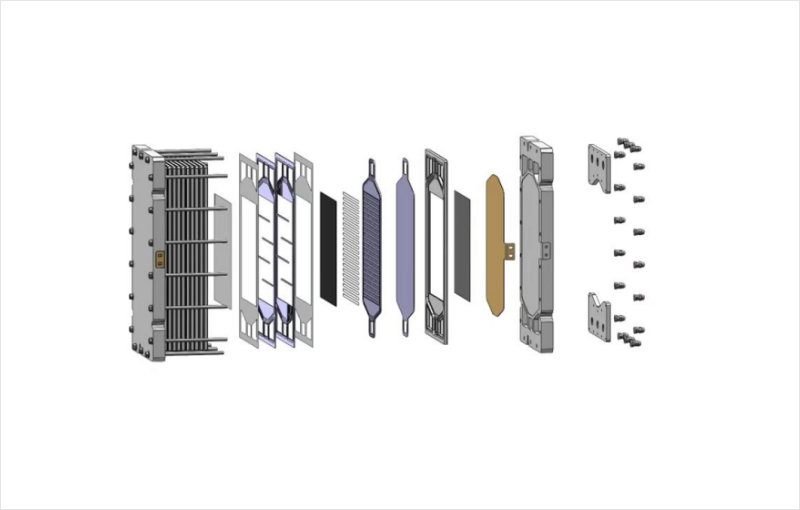

We have developed flexible graphite felt electrodes, semi CCM electrodes, and membrane electrodes for ALK, SE, and PEM electrolysis systems, achieving mass production of these three types of electrodes. Among them, the flexible graphite electrode catalyst has the characteristics of high loading and uniform distribution, high electrode active area, high conductivity, and strong chemical stability. Our proprietary membrane electrodes adopt an ordered catalytic layer structure, which reduces the noble metal loading of the anode catalytic layer. We employ multi-scale interface engineering strategy to regulate the gas liquid solid three-phase catalytic interface to enhance charge transfer kinetics and mass transfer efficiency. Additionally, we utilize computational fluid dynamics to construct a gas-liquid displacement transport model in a porous membrane electrode transport layer, optimizing the gas-liquid diffusion path, and achieving efficient discharge of reaction products.